Buying Guide for the Best Demolition Hammers

Choosing the right demolition hammer can make a significant difference in the efficiency and ease of your demolition projects. Demolition hammers are powerful tools designed to break down hard materials like concrete, brick, and stone. When selecting a demolition hammer, it's important to consider several key specifications to ensure you get the best fit for your needs. Understanding these specs will help you make an informed decision and choose a tool that matches the scale and nature of your work.Power (Wattage)Power, measured in watts, indicates the overall strength of the demolition hammer. Higher wattage means more power, which is essential for heavy-duty tasks. For light to medium demolition work, a hammer with 1000-1500 watts should suffice. For more demanding projects, look for models with 1500-2000 watts or more. Your choice should depend on the type of material you will be working with and the intensity of the job.

Impact Energy (Joules)Impact energy, measured in joules, determines the force with which the hammer strikes. This is crucial for breaking through tough materials. For lighter tasks, such as tile removal or small concrete slabs, 10-20 joules may be adequate. For more substantial demolition, like breaking up large concrete structures, look for hammers with 20-50 joules or more. Consider the thickness and hardness of the material you will be working on to choose the appropriate impact energy.

Blows Per Minute (BPM)Blows per minute (BPM) indicates how many times the hammer strikes per minute. A higher BPM can mean faster work, but it should be balanced with impact energy. For general demolition tasks, a BPM range of 1000-2000 is common. For more precise or delicate work, a lower BPM might be preferable. Think about the speed and precision required for your project when considering BPM.

WeightThe weight of the demolition hammer affects both its portability and ease of use. Lighter hammers (10-15 kg) are easier to handle and maneuver, making them suitable for overhead or extended use. Heavier hammers (15-30 kg) provide more impact force but can be tiring to use for long periods. Choose a weight that you can comfortably manage while still providing the necessary power for your tasks.

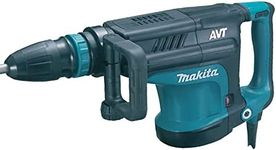

Handle Design and Vibration ControlHandle design and vibration control are important for user comfort and safety. Ergonomic handles reduce strain and fatigue, while vibration control features minimize the impact on your hands and arms. Look for models with cushioned grips and advanced vibration reduction technology if you plan to use the hammer for extended periods. This will help prevent injuries and make the tool more comfortable to use.

Bit CompatibilityBit compatibility refers to the types of bits the demolition hammer can use. Different tasks require different bits, such as chisels, points, or spades. Ensure the hammer you choose is compatible with the bits you need for your specific projects. Some hammers come with a variety of bits, while others may require separate purchases. Consider the range of tasks you will be performing and choose a hammer that offers the necessary bit options.

Durability and Build QualityDurability and build quality are crucial for a tool that will be subjected to heavy use. Look for demolition hammers made from high-quality materials with robust construction. Features like metal housings and reinforced components can extend the tool's lifespan. If you plan to use the hammer frequently or for large projects, investing in a durable model will save you money and hassle in the long run.