Buying Guide for the Best Home Cnc Machine

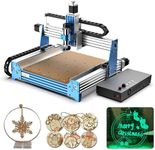

Choosing the right home CNC (Computer Numerical Control) machine can be a daunting task, but with the right knowledge, you can make an informed decision that suits your needs. CNC machines are used for cutting, carving, and milling various materials with high precision. When selecting a home CNC machine, it's important to consider several key specifications that will determine the machine's capabilities and suitability for your projects. Understanding these specifications will help you navigate the options available and choose the best fit for your requirements.Work Area SizeThe work area size refers to the maximum dimensions of the material that the CNC machine can handle. This is important because it determines the size of the projects you can work on. Work area sizes can vary from small (e.g., 12x12 inches) to large (e.g., 48x96 inches). If you plan to work on small, detailed projects like jewelry or small parts, a smaller work area may suffice. However, if you intend to create larger items like furniture or signs, you'll need a machine with a larger work area.

Spindle PowerThe spindle power indicates the strength of the motor that drives the cutting tool. It is measured in watts or horsepower. Higher spindle power allows the machine to cut through tougher materials and perform more demanding tasks. For light-duty projects involving soft materials like wood or plastic, a lower spindle power (e.g., 300-500 watts) may be adequate. For heavy-duty projects involving harder materials like metal, you'll need a higher spindle power (e.g., 1,000 watts or more).

Precision and AccuracyPrecision and accuracy refer to the machine's ability to follow the programmed design and produce consistent results. This is crucial for projects that require high levels of detail and exact measurements. Precision is often measured in microns or thousandths of an inch. Higher precision machines are ideal for intricate designs and detailed work, while lower precision may be acceptable for less detailed projects. Consider the level of detail required for your projects when evaluating this spec.

Material CompatibilityMaterial compatibility indicates the types of materials the CNC machine can work with, such as wood, plastic, metal, or composites. This is important because not all machines can handle all materials. If you primarily work with one type of material, ensure the machine is optimized for it. If you plan to work with a variety of materials, look for a versatile machine that can handle multiple types. Your project requirements will guide you in choosing a machine with the right material compatibility.

Software CompatibilitySoftware compatibility refers to the design and control software that the CNC machine can work with. This is important because the software is used to create and manage your designs. Some machines come with proprietary software, while others are compatible with popular third-party software. Ensure the software is user-friendly and meets your design needs. If you are already familiar with certain software, it may be beneficial to choose a machine that is compatible with it.

Build Quality and DurabilityBuild quality and durability refer to the construction and robustness of the CNC machine. A well-built machine will last longer and perform more reliably. Look for machines made with high-quality materials like aluminum or steel, and check for solid construction and stability. If you plan to use the machine frequently or for heavy-duty projects, durability becomes even more important. Assess the build quality to ensure the machine can withstand the demands of your work.

Ease of UseEase of use refers to how user-friendly the CNC machine is, including setup, operation, and maintenance. This is important, especially for beginners or those who prefer a straightforward experience. Look for machines with clear instructions, intuitive controls, and good customer support. If you are new to CNC machining, a machine with a simpler interface and easy-to-follow guides will be beneficial. Consider your comfort level with technology and choose a machine that matches your skill level.